Model Number: TE05-0501

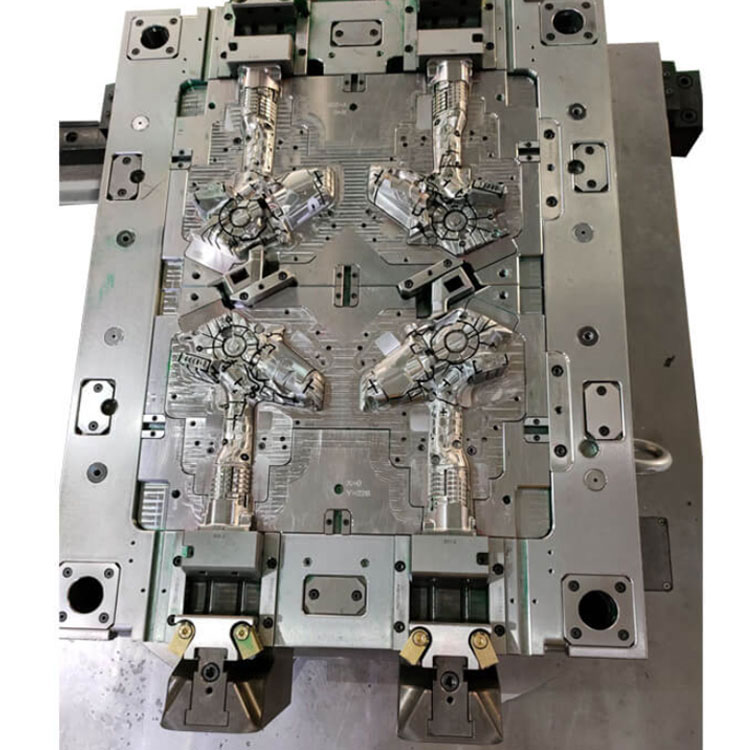

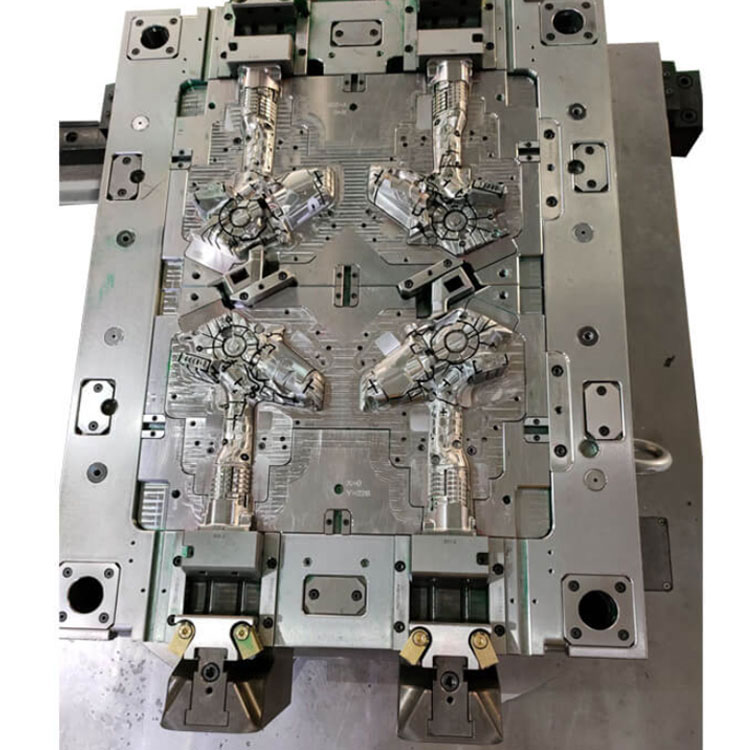

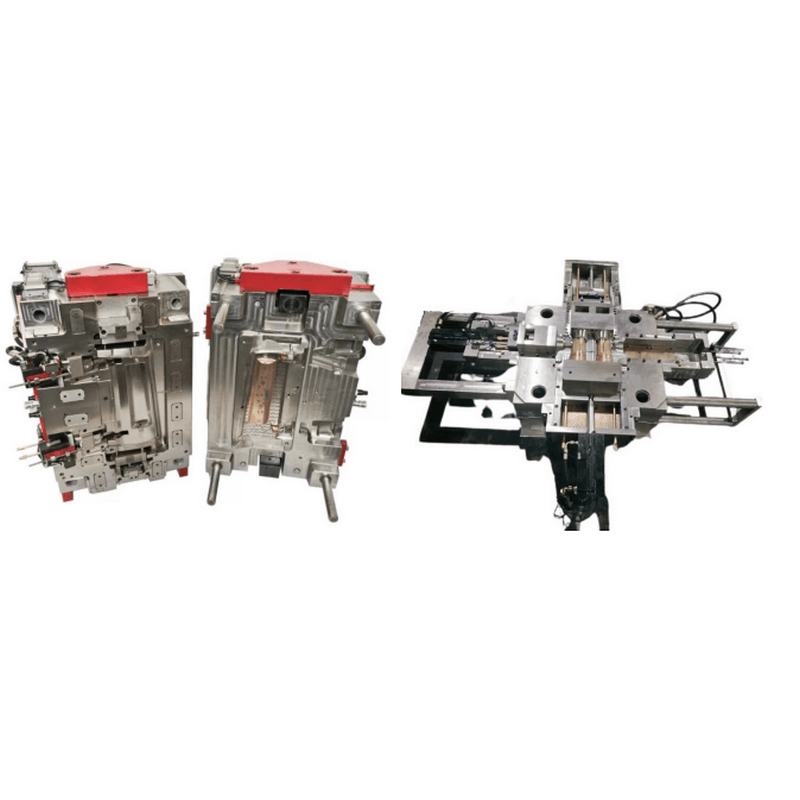

Product Name: 2K Mold

Brand Name: TTM

Mould Type: 2K Over Molding Mould

Mould Base: LKM, HASCO, DME, C50 standard mould base.

Mould Material: H13, 1.2344, 1.2738, P20, 45# according to customers’ requirement.

Mould Cavity: 4 Cavities

Mould Life: 100,000~500,000shots according to your requirement.

Mould Standard: HASCO, DME, MISUMI, LKM

Mould Size:

Plastic Parts Material: ABS, PP, PC, PA, PA66, POM, etc.

Port: Shenzhen

Lead Time: 4~5weeks

Brand | TTM |

Mould Base | LKM, HASCO, DME, C50 standard mould base |

Mould Material | H13, 1.2344, 1.2738, P20, 45#, etc., according to customers’ requirement. |

Mould Standard | HASCO, DME, MISUMI, LKM, etc. |

Product Material | ABS, PP, PC, PA, PA66, POM, etc. |

Runner | Cold/Hot Runner |

Gate Type | Side gate, sub gate, pin point gate, edge gate, etc. |

Mould Size(min) | 150*150mm |

Mould Size(max) | 1600*1200mm |

Mould Weight | 50~15,000 kg |

Injection Machine Type | 80~1500ton |

Certification | ISO9001:2015 |

Lead Time | 3~6weeks according to the product |

Two-shot high-precision injection molding is available

If you need to produce custom parts with multiple colors and different material characteristics, you may consider 2K, two-shot, or bi-injection molding. Unlike traditional processes, this technique involves the use of two barrels and nozzles in a single unit. Thus, two materials, that vary in colors, hardness features, and molecular structures, are injected into a mold one after another to form a unique plastic blend.

Our technology for two-shot precision injection molds ensures the flawless production of complex parts with enhanced copolymerization features. They are of importance when creating colorful designs and appealing styles. As part of bi-injection service, we use TPEs and plastics in a single cycle to improve your parts’ features in terms of:

- durability

- integrity

- aesthetic appeal

- material compatibility

It goes without saying that you’ll enjoy massive savings with our bi-injection service. As the end product is made close to perfection, you won’t have to spend much time assembling and finishing. These and many other production processes will be greatly optimized.

Stable production processes and high efficiency

Lower part cost compared with overmolding and assembly parts

Enhanced tactile and cosmetic product features

High precision and stable part quality

Improve the touch feel

Expanded design possibilities

Optimum bonding with minimum time and labor

2K injection mold and 2K injection molding process cost is higher than single injection molding, but the cost can be covered because of the assembly cost.

The combination between 2 plastic materials must be good

Tel

86-755-23579296

Mobile

13923763285

Contact Us

Susan Ho

Address

1st Floor, No. 208 Building, Yilong Road, Jinxia, Chang'an Town, Dongguan City, China