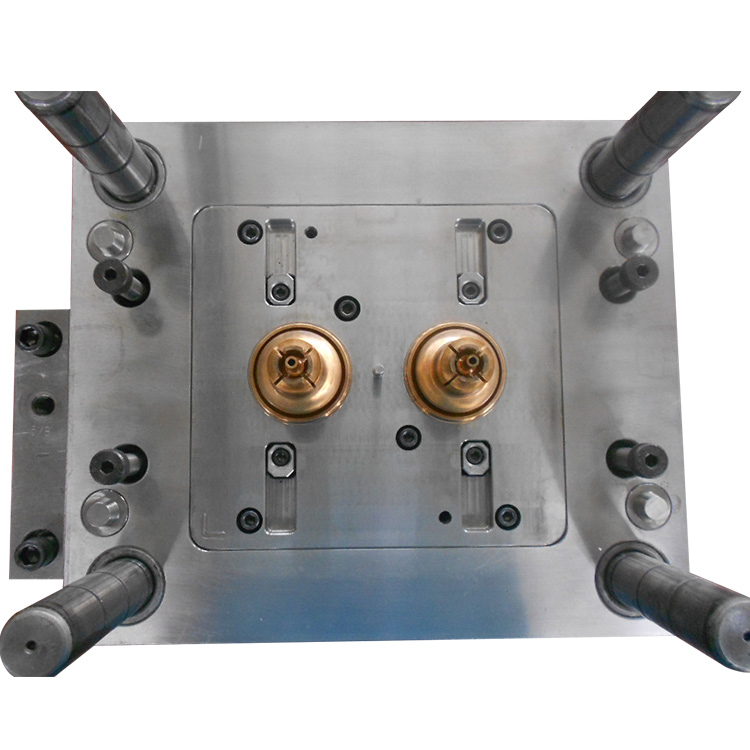

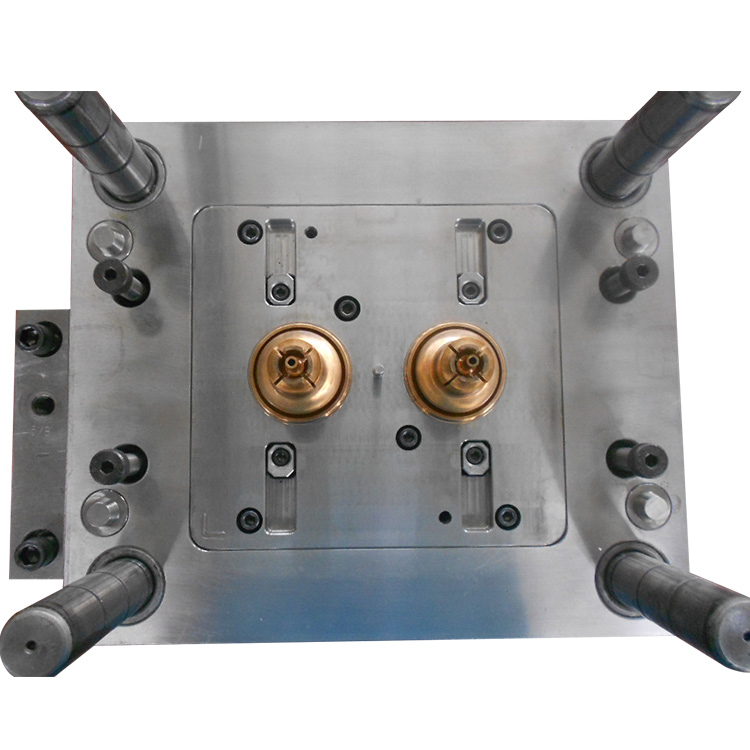

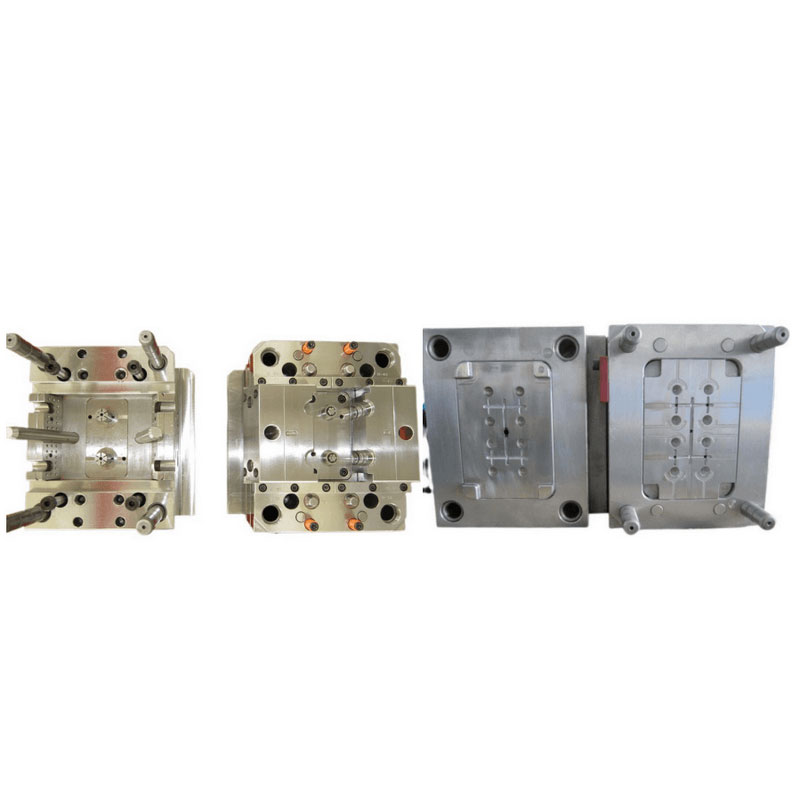

Model Number: TE08-0601

Product Name: Water Filter Cap

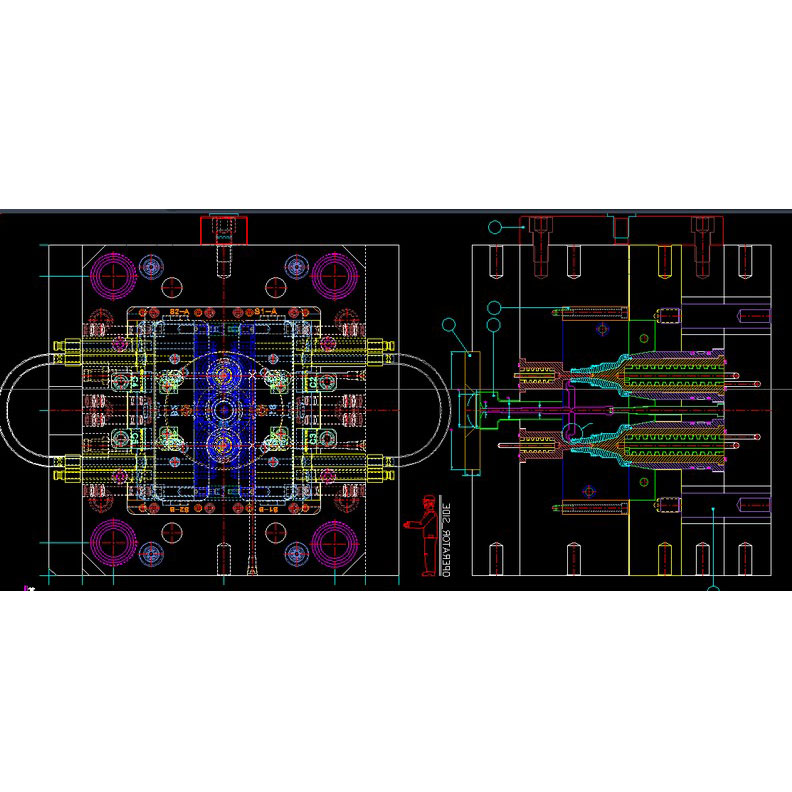

Mould Type: Hot Runner Mould

Mould Core and Cavity: H13

Mould Base: 1.1730

Cavity: 1+1

Injection System: Yudo Hot Runner

Plastic Parts Material: PP+ 20%GF

Mould Life: 500,000 Shots

Surface: Polish #400

Basic Information:

Brand | TTM |

Mould Base | LKM, HASCO, DME, C50 standard mould base |

Mould Material | H13, 1.2344, 1.2738, P20, 45#, etc., according to customers’ requirement. |

Mould Standard | HASCO, DME, MISUMI, LKM, etc. |

Product Material | ABS, PP, PC, PA, PA66, POM, etc. |

Runner | Cold/Hot Runner |

Gate Type | Side gate, sub gate, pin point gate, edge gate, etc. |

Mould Size(min) | 150*150mm |

Mould Size(max) | 1600*1200mm |

Mould Weight | 50~15,000 kg |

Injection Machine Type | 80~1500ton |

Certification | ISO9001:2015 |

Lead Time | 3~6weeks according to the product |

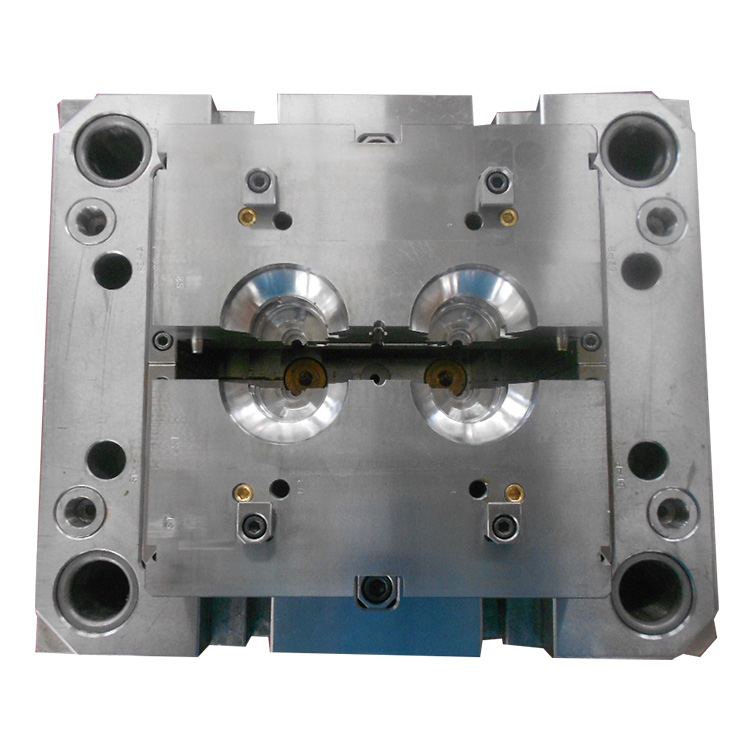

2 cavities hot runner mould made by Talent Mould.

1.High Quality OEM plastic Injection Water Filter mold / Cap Mould

2.Injection Design Manufacture of Custom Plastic Bottle Cap Mould

3.Customize bottle cap injection mold manufacturer

4.Plastic Cap mould

5. Water Filter mold

About your project:

Please kindly send me drawing files in step/ igs /x-t format or photos which will include clear hanger structure and dimension with below information, We can sign NDA to protect your copyright.

Our project manager having the following tasks / responsibilities:

● Project planning, reporting, change management and customer-interface organize and manage design & production reviews, try-outs with delivery of samples , final approval and mould delivery.

● Progress and status reports are issued each week including photos.

● Communication is done in English with marketing dept.

Tel

86-755-23579296

Mobile

13923763285

Contact Us

Susan Ho

Address

1st Floor, No. 208 Building, Yilong Road, Jinxia, Chang'an Town, Dongguan City, China